Views: 0 Author: Site Editor Publish Time: 2025-12-05 Origin: Site

Choosing the wrong geared slewing ring can lead to noise, wear, or even broken teeth. These failures often appear in tower cranes and other heavy machines. Many problems come from poor selection, not the bearing itself. In this post, you'll learn how to choose the right geared slewing ring with clear, practical steps.

Friction torque in geared slewing rings begins inside the bearing’s structure, and it grows from the way each part handles load, rotation, and contact pressure. When engineers understand how these components interact, they can choose a slewing ring that turns smoothly, resists wear, and avoids early failure. Problems seen in cranes—noise, sticking, tooth wear, or uneven rotation—often start here, inside the ring’s geometry, surface condition, and gear design.

Friction torque depends on how the bearing carries axial, radial, and moment loads. When these loads shift, the rolling elements create more resistance, and the ring begins to feel uneven. A geared slewing ring adds another layer: gear teeth transmit torque into the bearing, increasing contact forces at the tooth flank and raceway interface. Engineers evaluate this interaction carefully, because it shapes performance under slow rotation, heavy loads, and long duty cycles.

Each component contributes to torque generation, heat buildup, and wear patterns:

Component | Function | Influence on Friction Torque |

Inner / Outer Rings | Support loads and gear interface | Deformation increases resistance |

Rolling Elements (balls or rollers) | Reduce friction between raceways | Misalignment increases torque spikes |

Seals | Keep grease inside and contaminants out | Contamination raises torque |

Cages / Spacers | Maintain rolling element spacing | Uneven spacing causes vibration |

Mounting Holes | Connect bearing to structure | Poor flatness adds drag |

Rings deform slightly under load, and this deformation shifts rolling-element pressure. If installation is uneven, the raceway becomes tight in some areas and loose in others. This imbalance produces friction peaks during rotation, a pattern often noticed on tower cranes where torque rises sharply when the ring passes through a damaged or distorted raceway zone.

A slewing ring becomes “geared” when teeth are cut on either the inner or outer ring. These teeth deliver torque to the bearing, yet they also add friction sources, because tooth mesh forces react into the rolling elements.

● Internal gears sit inside the bearing. They protect the teeth from debris, reduce exposure, and support compact layouts.

● External gears provide more teeth, larger pitch diameters, and easier access for drives, common in tower cranes and wind turbines.

Applications such as cranes, turntables, and solar trackers often use geared rings because they require continuous, controlled rotation. When gear backlash is incorrect or tooth contact becomes uneven, torque increases sharply, and operators hear clicking or grinding as the pinion forces the ring over tight sections.

Engineers choose geared slewing rings when equipment needs torque transmission through a compact, load-bearing joint. They handle:

● High axial and radial loads along with strong moment forces.

● Slow rotation under heavy torque, where a standard bearing cannot provide geared drive.

These rings fit machines that combine rotation and structural support in one component. They help reduce system size, simplify drive layout, and eliminate external gearboxes. Compact systems—medical devices, small cranes, robotics—benefit from internal gears. Heavy machines—tower cranes, excavators, offshore platforms—prefer external gears for higher torque efficiency.

Because the bearing’s friction torque changes every time load, lubrication, or gear alignment shifts, selecting the right type becomes essential. Engineers look closely at gear position, tooth geometry, raceway hardness, and installation accuracy, since these factors directly shape torque behavior during rotation.

Selecting the right geared slewing ring requires a clear understanding of how loads, speed, gear design, and installation affect long-term performance. Each factor changes how the ring carries force, how smoothly it rotates, and how quickly it wears, especially in heavy machines where raceway deformation or tooth damage appears easily. Engineers study these variables early, because most failures begin long before the ring shows visible signs of distress.

Load calculations shape every part of slewing-ring performance, since the bearing must carry vertical, horizontal, and tilting forces together. When loads grow uneven, rolling elements push deeper into the raceway. It increases friction, heat, and deformation, especially under slow rotation. Overload may cause pitting, spalling, or a tight spot in the ring’s rotation path, a problem often seen in cranes where one side of the structure carries more weight than expected.

Gear design changes torque transmission and protection needs. Internal gears stay shielded, so they avoid dust, sand, and abrasive debris. This compact layout helps smaller machines, robots, or enclosed systems. External gears offer more teeth, larger diameters, and easier drive access. It creates higher torque efficiency, especially for cranes or wind turbines. The choice depends on torque demand, installation space, and environmental exposure.

Different machines rotate at very different speeds. Cranes turn slowly, so rolling elements cycle across the raceway under high load. It creates pitting and spalling over time. Faster automation systems run cleaner tracks, but they demand consistent lubrication and tighter tolerances. Engineers match the bearing to its duty cycle, including how often it reverses, stops, or carries shock loads.

Slewing rings rely on a flat, rigid mounting surface. When that surface is uneven, the ring bends slightly, and rolling elements face uneven pressure. It leads to noise, resistance, or jamming as the ring rotates. Bolt tightening must follow a diagonal sequence, and torque must stay balanced across the flange. Poor installation produces many failures seen in the field, including excessive clearance, frame tilt, or sudden raceway binding.

Backlash determines how smoothly the pinion and ring gear mesh. The typical target sits at 0.03–0.04 × module, a range that allows thermal expansion and load variation. Too little backlash forces the pinion tightly into the gear teeth, raising friction and heat. Too much backlash causes impact loads during starts and stops, which may break teeth or create loud, irregular noise. Engineers inspect tooth contact patterns to confirm alignment before operation.

Material quality shapes strength, fatigue life, and wear resistance. Raceway hardness depends on controlled induction hardening, where depth matters as much as hardness value. A shallow hardened layer may crack when loads increase. Gear teeth use similar treatments to resist early wear, especially in machines that reverse direction often. Each material choice affects how the ring handles stress cycles, lubrication, and corrosion.

Temperature shifts, moisture, dust, or chemicals influence the ring’s lifespan. Seals block contaminants, yet they fail when grease quality drops or distribution becomes uneven. Dry zones inside the raceway increase torque and accelerate wear. Machines in harsh environments need stronger sealing, more frequent lubrication, and grease formulas suited for extreme heat or cold. Proper maintenance prevents the early damage seen in many large slewing rings used outdoors.

Evaluating gear performance is essential for selecting a geared slewing ring that delivers stable torque, smooth rotation, and long service life. The gear interface carries heavy forces during operation, and even small alignment errors increase friction, noise, and stress. Engineers study gear geometry, contact patterns, and backlash to predict how the system behaves under load. Many failures seen in cranes and large equipment originate from poor gear evaluation rather than material defects, because gears transmit both torque and shock directly into the bearing.

Torque transmission depends on load, drive power, structural stiffness, and rotation frequency. Engineers calculate how much torque the pinion must deliver as the ring supports axial and moment loads. It becomes critical during low-speed operation, because rolling elements spend longer under concentrated force. Heavy-duty cranes require large torque capacity, while automation systems use smaller, faster gears. As torque increases, tooth pressure grows, and the system becomes more sensitive to gear accuracy, lubrication, and mounting quality.

These parameters define how the gear handles force. Larger modules create stronger teeth for heavy lifting equipment, while small modules support compact automation. Pitch diameter shapes torque leverage, so a larger diameter improves torque efficiency. Tooth count influences rotational smoothness and speed reduction. Engineers compare these values to their loading requirements, because an undersized gear cannot maintain stable contact. A table helps illustrate typical selections:

Gear mesh quality shows how the pinion and ring gear interact during rotation. Engineers apply marking compound to inspect contact patterns. A centered, even pattern indicates correct alignment. Partial contact reveals deeper issues. It may signal a bent pinion shaft, loose bolts on the drive, misaligned bearing installation, or deformation of the mounting structure. These conditions create tight spots or vibration as the ring moves. Uneven contact also accelerates raceway wear, since tooth forces push into the bearing at irregular angles.

Backlash ensures gears mesh without binding. It also prevents tooth impact when loads shift. Engineers measure backlash using feeler gauges inserted between mating teeth. The typical target sits near 0.03–0.04 × module, a range that balances clearance and stability. Too little backlash forces the teeth into constant friction, raising heat and noise. Too much backlash allows impact loads during reversing, which may break teeth or strip the gear surface. Incorrect backlash often appears after uneven installation, where bolts pull the ring out of round. Ensuring proper backlash stabilizes torque delivery and reduces shock transmitted into the slewing bearing.

Mounting arrangements shape how a geared slewing ring handles load, torque, and long-term alignment. The bearing transfers forces directly into the machine frame, so small installation errors quickly create noise, resistance, or uneven rotation. Many failures seen in cranes originate from improper mounting, not from defects in the bearing itself. Engineers examine drive position, bolt preload, gear protection, and frame stiffness to ensure stable operation under varying loads.

Drive position determines how easily the system can be serviced. An upper-structure drive offers easy access to motors and pinions, so maintenance becomes simple. It works well for cranes or rotating platforms where technicians reach the drive without disassembling the lower frame. A lower-structure drive keeps components protected, yet it may require more effort during service. Designers balance accessibility, torque demand, and shielding needs. Harsh environments may push the drive below the deck for extra protection, especially when dust or moisture threatens exposed gears.

Bolts hold the bearing firmly to the frame, and any uneven preload distorts the rings. Engineers select high-strength bolts sized for the loads produced during rotation and braking. A diagonal tightening pattern spreads preload evenly, preventing tilt and clearance variation. When preload shifts, the ring may bind, shake, or produce sharp noise as the rolling elements pass through tight areas. Technicians mark each bolt after tightening to track progress and confirm that torque remains consistent. A typical bolt control checklist is shown below:

Step | Purpose | Result |

Select bolt grade | Match load requirement | Prevent stretch or failure |

Apply lubrication | Improve torque accuracy | Reduce friction variation |

Tighten diagonally | Distribute load | Avoid ring distortion |

Mark bolts | Track torque completion | Confirm repeatability |

Gears operate best when protected from debris, moisture, or abrasive particles. External gears often use shrouds, covers, or rubber skirts to block contamination. These shields reduce wear and help maintain smooth mesh. Internal gears naturally remain protected, since they sit inside the bearing structure. This makes them ideal for dirty or confined environments where sand, metal shavings, or concrete dust may enter exposed teeth. Engineers match protection needs to operating conditions, because contamination increases torque and accelerates pitting on both teeth and raceways.

The bearing depends on a stiff, flat mounting frame. Weak frames bend under load, creating uneven raceway contact and sudden resistance. This bending forces rolling elements into tight zones, so the ring may feel notchy or produce vibration. Technicians use dial indicators to detect excessive clearance changes, which often point to frame deformation instead of bearing failure. Machines may also shake when the frame lacks rigidity, even when the bearing is correctly installed. Strengthening the frame restores stability and helps the slewing ring rotate smoothly under heavy loads.

Geared slewing rings fail for many reasons, yet most issues begin long before visible damage appears. Many failures come from incorrect sizing, poor mounting, or mismatched gear geometry, not from defects in the bearing itself. Engineers reduce these risks by understanding how loads, lubrication, alignment, and structural stiffness interact inside the ring. When each factor aligns correctly, the bearing rotates smoothly, carries heavy loads, and maintains stable gear mesh under varying conditions.

Raceway damage usually forms when loads exceed the bearing’s design capacity. Excessive axial or moment load pushes balls or rollers deeper into the raceway, which increases stress. Poor lubrication adds friction, so metal-to-metal contact forms tiny pits. Heat treatment issues, such as shallow hardened layers, allow cracks to grow under repeated stress. Slow-turning machines, including cranes, show pitting early because rolling elements stay under high load for long periods. Engineers avoid these failures by selecting a ring sized for peak loads, using correct grease, and confirming that heat treatment supports heavy-duty operation.

Noise often points to installation issues. A slewing ring needs a flat, rigid surface, yet many frames introduce uneven pressure. When preload shifts, the ring binds slightly as it turns, and operators hear scraping or clicking. Foreign objects inside the raceway also create noise, especially if debris enters during handling. A dry raceway increases friction, so the ring grinds as the elements pass through dry spots. Uneven torque on bolts twists the ring out of shape. These conditions disappear when the mounting surface stays flat, grease distribution is complete, and bolts follow a controlled tightening sequence.

Gear teeth fail when mesh geometry becomes incorrect. Improper backlash forces the pinion tightly into the ring gear, creating high pressure on the tooth flank. A misaligned pinion axis shifts contact toward one side of the tooth, so the load becomes concentrated. Machines that frequently start, stop, or reverse generate impact loads that accelerate wear. If backlash grows too large, teeth slam into each other each time the drive reverses. Engineers prevent breakage by inspecting contact patterns, using feeler gauges to confirm backlash, and verifying that pinion support structures remain stiff enough to hold alignment.

Tilt or shaking often appears after installation when the bearing frame lacks stiffness. Weak structures bend under load, and the ring develops uneven clearance around its circumference. Technicians measure clearance using dial indicators placed at multiple points. If readings vary sharply, the ring or frame may be distorted. Loose bolts also produce tilt, since preload drops and the bearing loses uniform support. Shaking may come from the frame itself, even when the bearing is healthy. Engineers eliminate these issues by reinforcing the frame, tightening bolts correctly, and confirming that all mounting surfaces stay flat under working load.

Tip: Always inspect mounting flatness and gear backlash before first operation, because most early failures start from installation errors, not bearing design.

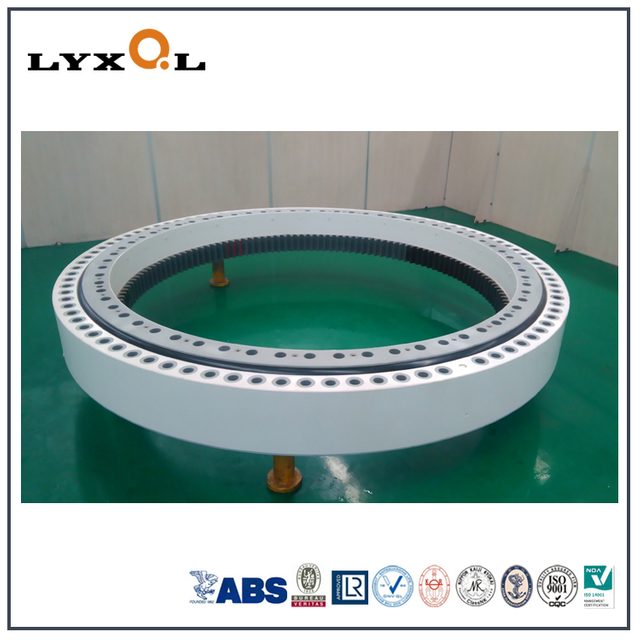

Choosing geared slewing rings requires careful attention to load, gear performance, installation accuracy, and environment. Many failures like noise, tooth damage, and pitting come from poor selection or incorrect installation, not the bearing itself. A systematic evaluation improves long-term reliability. LYXQL provides durable solutions and expert support to help users achieve stable performance and lasting value.

A: Geared slewing rings are bearings with internal or external gears used for rotation under heavy loads. Choosing the right geared slewing rings ensures proper torque, smooth motion, and long service life.

A: Select geared slewing rings based on load, torque, gear type, backlash, and mounting accuracy to prevent noise, tooth wear, and raceway damage.

A: Poor flatness, uneven bolt torque, or incorrect backlash can affect geared slewing rings, leading to vibration, noise, or binding.

A: Internal gears offer protection in harsh environments, while external geared slewing rings provide higher torque capacity and easier maintenance.