Views: 0 Author: Site Editor Publish Time: 2025-08-01 Origin: Site

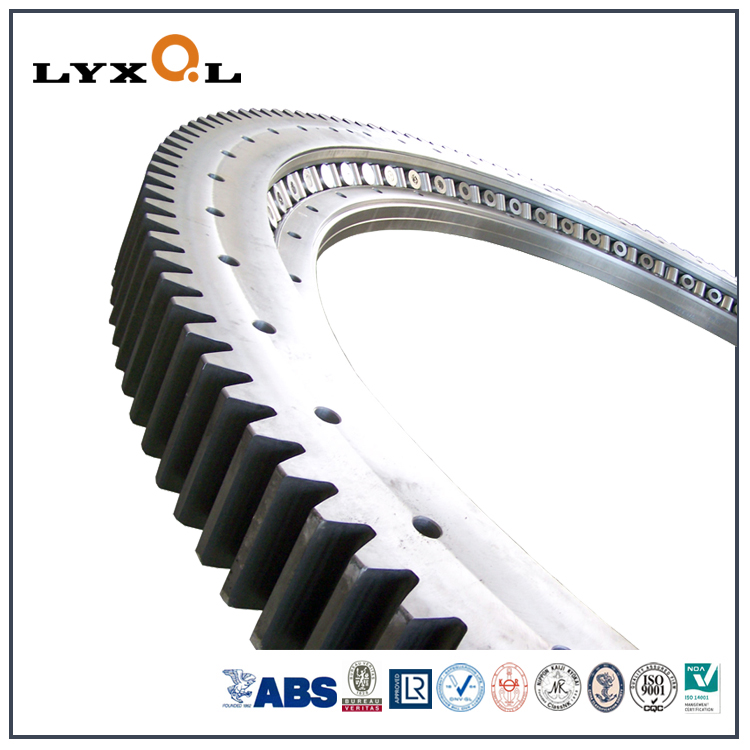

Do you know what makes cranes and wind turbines rotate smoothly? It's slewing bearings. Choosing the right supplier is crucial for performance and cost-effectiveness. LYXQL, with its expertise and competitive pricing, is a preferred choice. In this article, you'll learn why selecting LYXQL for slewing bearings ensures quality and value.

When it comes to slewing bearings, choosing the right supplier makes all the difference. LYXQL stands out for several key reasons:

LYXQL brings years of experience crafting slewing bearings designed for durability and performance. Their team understands the intricacies of bearing design and manufacturing processes, ensuring each product meets industry standards. This expertise translates to bearings that can handle heavy loads and tough conditions, making them a reliable choice for various machinery.

Quality is never compromised at LYXQL. Each slewing bearing undergoes strict quality control and testing procedures. This includes material inspections, dimensional accuracy checks, and performance tests under simulated load conditions. These steps guarantee that every bearing delivers smooth rotation, long service life, and resistance to wear.

For example, LYXQL uses advanced heat treatment and precision grinding to enhance hardness and surface finish. This reduces friction and extends bearing life, even in harsh environments.

LYXQL offers competitive prices without sacrificing quality. By optimizing their manufacturing processes and maintaining strong supplier relationships, they reduce costs and pass those savings to customers. Plus, they provide flexible pricing options for bulk orders or long-term partnerships, helping businesses manage budgets effectively.

In addition, LYXQL’s direct factory sales model eliminates middlemen, ensuring transparent pricing and better deals. This approach benefits customers seeking cost-effective solutions without hidden fees.

When considering slewing bearings, several key factors influence their price. Understanding these can help you make informed choices when selecting bearings from LYXQL or any other supplier.

The materials used play a huge role in cost. High-quality slewing bearings often use alloy steels like 42CrMo or 50Mn. These materials provide excellent strength, hardness, and fatigue resistance. LYXQL employs advanced heat treatment and precision grinding to improve surface finish and durability, which adds value but also impacts the price.

Manufacturing processes matter too. Precision machining, such as CNC gear cutting and raceway grinding, ensures tight tolerances and smooth operation. More complex processes increase costs but result in longer-lasting, reliable bearings. LYXQL’s in-house production and strict quality controls help balance quality and cost effectively.

Size directly affects price. Larger slewing bearings require more raw material and longer machining times. They also need to support higher loads, which means thicker rings and more robust rolling elements.

Load capacity is another factor. Bearings designed for heavy axial, radial, and moment loads often have multiple rows of rollers or balls. For example, single-row ball bearings cost less than three-row roller bearings, which can handle much higher loads but require more material and manufacturing complexity.

LYXQL offers a wide range of sizes and load capacities, ensuring customers pay only for what their application demands.

The type of slewing bearing influences price too. Common designs include:

Single-row ball bearings: Simple, cost-effective for light to medium loads.

Double-row ball bearings: Higher load capacity, moderate price increase.

Four-point contact ball bearings: Handle axial, radial, and moment loads compactly; mid-range pricing.

Crossed roller bearings: High precision and rigidity; more expensive due to complex roller arrangement.

Three-row roller bearings: Heavy-duty, highest price, designed for extreme loads.

Each design suits different applications and budget levels. LYXQL’s expertise allows them to recommend the best type balancing performance and cost.

Customization also affects price. Adding special seals, coatings, or gear teeth can increase costs but improve performance and lifespan.

Slewing bearings play a vital role across many industries. They help machines rotate smoothly while carrying heavy loads. Here are some key applications where slewing bearings prove essential:

Construction machines like cranes, excavators, and loaders rely heavily on slewing bearings. These bearings allow the upper structure to rotate on the base, enabling precise positioning and movement. For example:

Cranes use slewing bearings to rotate the boom and lift heavy loads safely.

Excavators depend on them for smooth swing motion, improving digging efficiency.

Loaders use slewing bearings to rotate the bucket or arm, enhancing handling.

Because construction equipment faces tough conditions, slewing bearings must be durable and reliable. LYXQL bearings, made with high-quality materials, ensure long service life and consistent performance under heavy stress.

Wind turbines depend on slewing bearings for two main functions:

Yaw system: This system rotates the nacelle to face the wind direction, maximizing energy capture.

Pitch system: It adjusts blade angles to control speed and load on the turbine.

Slewing bearings in turbines must handle axial, radial, and moment loads while resisting harsh weather and corrosion. LYXQL’s advanced manufacturing ensures bearings meet these demands, supporting turbine efficiency and longevity.

Robotics and automation require precise, smooth rotation for arms, turntables, and platforms. Slewing bearings provide:

High rotational accuracy

Compact design fitting tight spaces

Ability to handle combined loads during movement

For example, robotic arms in assembly lines use slewing bearings to rotate joints smoothly while carrying tools or parts. LYXQL offers customized slewing bearings tailored for automation, helping machines achieve high precision and repeatability.

When choosing slewing bearings from LYXQL, customization options and additional features play a big role in tailoring the product to your unique needs. These choices can impact both price and performance, so it's important to understand what’s available.

LYXQL offers a wide range of custom slewing bearing designs. Whether you need a specific diameter, bolt hole pattern, or gear type, they can create bearings that fit your exact application. For example:

Custom ring thickness for added strength

Modified gear teeth profiles for special drive systems

Unique mounting hole arrangements to fit unusual frames

This flexibility ensures you get a bearing that integrates perfectly into your machinery, reducing installation hassles and improving overall reliability.

Adding features such as seals and protective coatings can greatly enhance bearing life and performance. LYXQL provides:

Sealing options: These prevent dirt, dust, and moisture from entering the bearing, which reduces wear and maintenance needs. Seals are especially important in harsh environments like construction sites or offshore wind farms.

Corrosion-resistant coatings: Ideal for bearings exposed to water, salt, or chemicals. Coatings like black oxide or specialized paints protect against rust and surface damage.

Lubrication systems: Some bearings come with grease nipples or even automatic lubrication setups for continuous maintenance-free operation.

These features help bearings operate smoothly longer, lowering downtime and repair costs.

Custom features usually increase the initial price, but they often save money in the long run by extending service life and reducing failures. For instance:

A sealed bearing might cost 10-20% more upfront but can last twice as long in dusty conditions.

Special coatings add a small premium but prevent corrosion-related breakdowns.

LYXQL balances cost and quality by using advanced manufacturing techniques and in-house production. This approach keeps customized bearing prices competitive without sacrificing durability or precision.

Global market trends heavily influence slewing bearing prices. Factors like raw material costs, trade policies, and international demand shifts can cause price fluctuations. For example, steel price surges or supply chain disruptions often increase manufacturing expenses. These changes ripple down to customers, affecting budgets and project timelines.

Economic uncertainties, such as tariffs or geopolitical tensions, can also impact availability and cost. During high-demand periods, scarcity might push prices higher. Conversely, market slowdowns may lead to more competitive pricing.

LYXQL understands these challenges and takes proactive steps to ensure supply chain stability. They maintain strong relationships with trusted raw material suppliers, securing priority access and favorable pricing. This strategy helps buffer against sudden market swings.

Additionally, LYXQL invests in advanced inventory management and production planning. By forecasting demand and optimizing stock levels, they minimize delays and prevent shortages. Their vertically integrated manufacturing process reduces reliance on external vendors, further enhancing control over quality and delivery.

They also monitor global logistics closely, adapting quickly to transportation issues or regulatory changes. This agility ensures continuous production flow and timely fulfillment.

Timely delivery is crucial for project success. LYXQL prioritizes efficient order processing and streamlined logistics. Their global distribution network covers major regions, enabling fast shipping and reduced transit times.

Customers benefit from real-time order tracking and responsive communication. LYXQL’s commitment to on-time delivery helps avoid costly downtime and keeps operations running smoothly.

Moreover, they offer flexible production schedules to accommodate urgent or large-volume orders. This responsiveness supports diverse client needs across industries like construction, wind energy, and automation.

When it comes to buying slewing bearings, LYXQL offers several advantages that make the purchasing process smooth, cost-effective, and reliable.

Buying directly from LYXQL means you cut out middlemen, which often leads to better prices and clearer communication. You get factory-direct access to their full product range, ensuring authenticity and quality. This direct connection also means faster response times for inquiries, technical support, and after-sales service. Plus, you can discuss your specific needs directly with their experts, helping you choose the right bearing for your application without confusion.

If your project requires multiple slewing bearings, LYXQL provides attractive bulk order discounts. These discounts help reduce your overall cost per unit, making large-scale procurement more budget-friendly. They also offer flexible payment terms and special deals for long-term partnerships. Whether you’re an OEM or a large construction firm, LYXQL tailors pricing and delivery options to fit your procurement strategy. Bulk orders often come with priority production scheduling, reducing lead times and ensuring your project stays on track.

LYXQL supports worldwide shipping, so no matter where your operation is located, they can deliver your slewing bearings reliably and on time. Their logistics network includes partnerships with major freight carriers, ensuring safe and efficient transportation. They provide tracking services, so you can monitor your shipment from factory to site. Additionally, LYXQL offers tailored packaging solutions to protect bearings during transit, especially for sensitive or customized products.

They understand the importance of timely delivery in industries like construction, wind energy, and automation. That’s why they maintain production flexibility to handle urgent orders and coordinate with customers on delivery schedules. Their supply chain management minimizes delays caused by customs or transportation issues.

Choosing LYXQL Slewing Bearing Co., Ltd. offers numerous benefits, including expertise in manufacturing, rigorous quality assurance, and competitive pricing. Their slewing bearings are designed to handle heavy loads and tough conditions, making them ideal for various applications. With options for customization and global shipping, LYXQL provides reliable solutions tailored to your needs. For the best deals and expert consultation, consider LYXQL for your slewing bearing requirements. Contact them today for a personalized quote and experience their exceptional service.

A: LYXQL ensures reliability through expert manufacturing, rigorous testing, and quality assurance processes.

A: LYXQL offers competitive pricing by optimizing manufacturing and using a direct factory sales model.

A: Yes, LYXQL provides custom designs and additional features like seals and coatings.

A: LYXQL bearings are used in construction machinery, wind turbines, robotics, and automation.