Views: 0 Author: Site Editor Publish Time: 2025-08-04 Origin: Site

Have you ever wondered how massive cranes or wind turbines smoothly rotate? The secret lies in slewing bearings. These critical components enable the rotation of heavy machinery parts. In this post, we’ll explore what slewing rings are, their crucial role in machinery, and the various sizes they come in. You'll learn how these bearings support diverse applications, from construction to aerospace.

Slewing ring size depends on several key factors. First, the load it must carry plays a big role. This includes axial loads (forces along the axis), radial loads (forces perpendicular to the axis), and overturning moments (twisting forces). The heavier or more complex the load, the larger and stronger the slewing ring needs to be.

Next, the application’s design and space constraints affect size. For example, compact machinery requires smaller slewing rings, while large construction equipment can accommodate bigger ones. The speed and range of rotation also influence size choices. Rings designed for slow, heavy loads tend to be larger to distribute forces better.

Material quality and manufacturing precision impact size as well. High-grade materials allow slewing rings to be smaller while still handling heavy loads, thanks to better strength and durability. Manufacturers often balance these factors to optimize performance and cost.

Slewing rings come in a wide range of sizes to fit various industries:

Construction Equipment: Sizes range from about 0.5 meters (20 inches) on small excavators to over 6 meters (20 feet) on massive mining machines. These rings must handle heavy loads and constant movement.

Renewable Energy: Wind turbines use slewing rings typically between 1 and 5 meters in diameter. These rings support the turbine’s yaw and pitch mechanisms, needing precision and durability.

Aerospace: Slewing rings in aerospace are smaller but highly precise, often under 0.5 meters. They must withstand high speeds and tight tolerances for satellite positioning and aircraft assembly.

Industrial Robotics and Machinery: Sizes vary widely from a few centimeters to over a meter, depending on the robot’s size and function. Precision and smooth rotation are critical here.

Sometimes, standard sizes don’t fit unique requirements. Custom slewing rings are designed to match exact specifications, including diameter, thickness, gear teeth count, and mounting hole patterns. Customization ensures optimal performance, longer lifespan, and better integration.

Manufacturers work closely with clients to analyze load conditions, environmental factors, and operational needs. For instance, a slewing ring used in offshore wind turbines might need corrosion-resistant materials and special seals, affecting size and design.

Customization also allows for innovations like integrated sensors for condition monitoring or specialized lubrication systems. These features help extend service life and reduce maintenance.

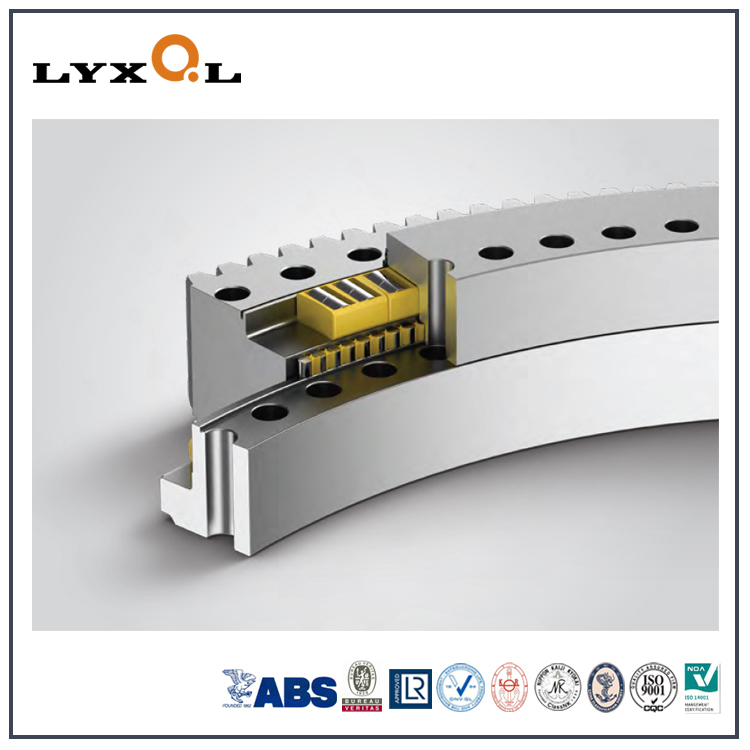

Slewing rings come in several types, each designed for specific load requirements and applications. Understanding these types helps you choose the right bearing size and style for your machinery.

These bearings have a single row of balls as rolling elements. They are versatile and widely used because they handle axial, radial, and moment loads efficiently. Their design is relatively simple, making them cost-effective.

Inner Diameter Range: 120 mm to 4272 mm

Outer Diameter Range: 300 mm to 4845 mm

Material: Typically made from high-strength steel like 50Mn or 42CrMo

Sealing: Double-sided sealing protects against dirt and debris

Single row ball bearings suit applications with moderate load demands, such as medium-sized construction equipment or industrial machinery.

Cross roller bearings use cylindrical rollers arranged at right angles, allowing them to handle heavier loads and moments than ball bearings of similar size. Their compact design supports high rigidity and precision.

Inner Diameter Range: 398 mm to 4272 mm

Outer Diameter Range: 629 mm to 4845 mm

Material: High-quality steel like 50Mn and 42CrMo

Sealing: Double-sided sealing to maintain lubrication and prevent contamination

These bearings are excellent in robotics, machine tools, and aerospace where precision and load capacity matter.

Featuring two rows of balls, these bearings increase load capacity and durability. They can carry heavier axial and radial loads and larger overturning moments compared to single row types.

Inner Diameter Range: 384 mm to 4222 mm

Outer Diameter Range: 644 mm to 4895 mm

Material: 50Mn or 42CrMo steel for strength and wear resistance

Sealing: Double-sided sealing ensures long service life

Double row ball bearings are common in large cranes, excavators, and wind turbines where reliability under heavy loads is essential.

These bearings contain three rows of rollers, providing the highest load capacity among slewing rings. They handle large axial, radial, and moment loads, making them ideal for the most demanding applications.

Inner Diameter Range: 366 mm to 4218 mm

Outer Diameter Range: 664 mm to 4895 mm

Material: High-grade steel such as 50Mn or 42CrMo

Sealing: Double-sided sealing for protection and lubrication retention

Three-row roller bearings are often used in heavy machinery like large excavators, mining equipment, and industrial turntables.

Slewing rings come in various sizes, each suited to different applications. Their size affects how they perform in specific industries and machinery. Let’s explore how different sizes fit into construction, renewable energy, aerospace, and industrial uses.

Construction machines like excavators, cranes, and loaders rely heavily on slewing rings. These rings handle huge loads and allow parts to rotate smoothly. Larger machines need bigger slewing rings, sometimes over 6 meters in diameter, to support heavy weight and constant movement.

For example, a small excavator might use a slewing ring around 0.5 meters wide. In contrast, mining excavators may require rings exceeding 6 meters. The size ensures stability and durability during tough jobs like digging, lifting, and rotating heavy materials.

Renewable energy equipment, especially wind turbines, depends on slewing rings to function efficiently. These rings support the yaw and pitch systems, helping turbines face the wind and adjust blade angles.

Typically, slewing rings in wind turbines range from 1 to 5 meters in diameter. This size balances strength and precision. The rings must endure harsh weather and continuous rotation, so they are often made from corrosion-resistant materials and sealed tightly to prevent damage.

Solar trackers also use smaller slewing rings to adjust panels toward the sun throughout the day. These rings are generally smaller but still need to be reliable and low maintenance.

Aerospace demands small, precise slewing rings. These are usually under 0.5 meters in diameter. They must handle high speeds and exact positioning, such as in satellite dishes or aircraft assembly robots. Even though these rings are smaller, they require top-quality materials and manufacturing to meet strict standards.

Industrial robots and machinery use slewing rings ranging from a few centimeters to over a meter. The size depends on the robot’s function and load. Smooth rotation and compact design are critical here, so the rings are designed for precision and durability.

Slewing rings are built to handle heavy loads and constant movement, so material choice is crucial. Most slewing rings use high-strength steel alloys like 50Mn or 42CrMo. These steels offer excellent toughness, wear resistance, and fatigue strength. Sometimes, manufacturers apply heat treatments to improve hardness and durability.

For specialized environments, materials may vary. For example, corrosion-resistant steels or coatings are common in offshore or renewable energy applications. Lightweight alloys or stainless steel might be used in aerospace or medical equipment, where weight and corrosion resistance matter more.

The rolling elements inside—balls or rollers—are also made from hardened steel to withstand friction and stress. Seals and lubrication components often use synthetic materials designed to resist contamination and maintain performance over time.

Producing slewing rings requires precision and strict quality control. Manufacturers follow industry standards like ASME SRB-1, which sets guidelines for design, installation, and maintenance. These standards ensure slewing rings meet safety and performance criteria.

Each ring undergoes multiple inspections during production. Dimensional checks verify the inner and outer diameters, thickness, and mounting hole placement. Gear teeth are measured for accuracy to ensure smooth engagement with drive gears.

Non-destructive testing methods such as magnetic particle inspection or ultrasonic testing detect cracks or flaws in the metal. Additionally, manufacturers test the bearing's rotation and measure any play or tolerance to confirm smooth operation.

Lubrication systems and seals are also tested to ensure they keep contaminants out and retain grease inside. This helps prevent premature wear and extends the ring’s service life.

Recent innovations have improved slewing ring manufacturing in several ways. Computer-aided design (CAD) and computer numerical control (CNC) machining allow for highly precise components, reducing errors and improving fit.

Advanced heat treatment processes enhance material properties, making rings stronger and more resistant to wear. Some manufacturers now use segmented rings for very large diameters, easing transportation and assembly.

Additive manufacturing (3D printing) is emerging for prototypes or complex parts, speeding up development cycles. Smart technology integration, such as embedded sensors, enables real-time condition monitoring. This helps detect lubrication issues or wear early, preventing failures.

Environmental considerations also drive improvements. Manufacturers are adopting greener processes and materials, reducing waste and energy use.

Proper lubrication plays a crucial role in extending the life of slewing rings. These bearings operate under heavy loads and constant movement, which generate friction and heat. Without adequate lubrication, the rolling elements and raceways wear quickly, leading to premature failure.

Lubricants reduce friction by forming a protective film between moving parts. This film prevents metal-to-metal contact, minimizing wear and corrosion. Using the right grease or oil, applied at correct intervals, ensures smooth operation and prevents damage from contaminants like dirt or moisture.

In many applications, especially heavy machinery like excavators or cranes, lubrication must be checked regularly. Some slewing rings come with grease fittings to simplify maintenance. Automated lubrication systems are also available for continuous grease supply, reducing manual effort and avoiding lubrication lapses.

Regular inspections help catch small issues before they become costly repairs. Maintenance teams should look for signs such as unusual noises, increased play or backlash, and visible damage to seals or mounting bolts.

Key maintenance tips include:

Check for Proper Lubrication: Inspect grease levels and replenish as needed. Look for grease leakage or contamination.

Inspect Seals: Seals protect internal components from dirt and water. Damaged seals allow contaminants to enter, accelerating wear.

Monitor Bearing Play: Excessive play indicates wear or loosening of mounting bolts. Tighten bolts according to manufacturer specs.

Clean the Bearing Area: Remove dirt, debris, and rust around the slewing ring to prevent contamination.

Check Gear Teeth and Drive Components: Ensure gear teeth are undamaged and properly engaged to avoid uneven wear.

Scheduling maintenance based on operating hours or environmental conditions helps keep slewing rings in top shape. For example, machines in dusty or wet environments may require more frequent checks.

Slewing rings may encounter several common problems during their service life:

Insufficient Lubrication: Leads to increased friction, overheating, and accelerated wear. Symptoms include grinding noises and rough rotation.

Contamination: Dirt, water, or metal particles inside the bearing cause pitting and corrosion. This reduces bearing life.

Seal Failure: Damaged seals allow contaminants in and lubricants out. This results in poor lubrication and bearing damage.

Bolt Loosening: Loose mounting bolts cause misalignment and uneven load distribution, leading to premature failure.

Wear and Fatigue: Over time, material fatigue or wear can cause cracks or deformation in raceways or rolling elements.

Troubleshooting starts by identifying symptoms early. Vibration analysis and regular measurements of bearing play can detect issues before failure. Replacing damaged seals, re-lubricating, and tightening bolts often solve many problems. In severe cases, bearing replacement may be necessary.

Slewing ring technology keeps evolving to meet growing industry demands. Manufacturers focus on improving strength, precision, and durability. Advanced materials like high-grade steels and composites help create lighter yet stronger rings. This reduces overall machine weight while maintaining load capacity.

Precision machining techniques, such as CNC, allow for tighter tolerances and better gear tooth profiles. These improvements enhance smooth rotation and reduce wear. Segmented slewing rings are becoming more popular for very large diameters. They simplify transport and installation without sacrificing performance.

Another trend is integrating condition monitoring sensors into slewing rings. These sensors track temperature, vibration, and lubrication status in real time. Early detection of issues helps prevent costly failures and downtime. This smart technology enables predictive maintenance, saving time and money.

Smart technology transforms how slewing rings operate and are maintained. Embedded sensors provide continuous data on operational conditions. This data feeds into software systems that analyze bearing health and predict maintenance needs.

For example, if sensors detect increased vibration or heat, it signals possible wear or lubrication problems. Operators receive alerts to inspect or service the ring before failure occurs. This approach extends service life and improves machine reliability.

Additionally, smart slewing rings can communicate with other machine components. This integration supports automated adjustments for optimal performance. It also helps in remote diagnostics, reducing the need for on-site inspections.

Looking ahead, slewing rings will play a vital role in emerging technologies. Autonomous construction equipment, advanced robotics, and renewable energy systems will demand rings that combine high precision, strength, and smart features.

Research into new materials, such as ceramics or carbon-fiber composites, could further reduce weight and increase durability. Additive manufacturing (3D printing) may allow for complex, custom designs that traditional methods cannot produce easily.

Furthermore, slewing rings might incorporate self-lubricating materials or advanced sealing systems to minimize maintenance needs. This is crucial for applications in harsh or remote environments, such as offshore wind farms or space exploration.

In summary, the future of slewing ring technology lies in smarter, stronger, and more adaptable designs. These advances will support a wide range of industries, improving machine efficiency, safety, and lifespan.

Slewing rings come in various sizes, influenced by load, application design, and material quality. Choosing the right size ensures optimal performance and longevity in construction, renewable energy, aerospace, and industrial applications. Selecting the appropriate slewing ring size is crucial for efficiency and safety. LYXQL Slewing Bearing Co., Ltd. offers customized solutions, ensuring durability and precision. Their advanced manufacturing techniques and high-quality materials provide exceptional value, making them a reliable choice for diverse industry needs.

A: Load capacity, application design, space constraints, speed, and material quality impact slewing ring size.

A: High-strength steel alloys like 50Mn or 42CrMo are typically used for their toughness and durability.

A: Smart sensors provide real-time data for predictive maintenance, improving reliability and lifespan.

A: Lubrication reduces friction and wear, preventing premature failure and ensuring smooth operation.