Luoyang Xinqianglian Slewing Bearing Co., Ltd. ( Hereinafter referred to as the LYXQL) founded in 2003, is located in the ancient capital of nine dynasties Luoyang in Henan province. LYXQL is a national key high-tech enterprises and become a GEM listing company successfully on July 13,2020 (stock code "300850").

LYXQL is a leader in the manufacturers of large size slewing bearings, based on Luoyang in China, developing and producing slewing bearings and precision bearings for the most varied of application areas. The slewing bearings are widely used as components in cranes.

Cranes are lifting machinery used in highway and bridge engineering construction. According to its structure and characteristics, it can be generally divided into four categories: light and small lifting equipment, bridge cranes, gantry cranes and tower cranes.

The slewing bearing is an important "joint" of the crane, so its maintenance is very important. The working characteristics of cranes are intermittent movement, that is, the corresponding mechanisms of reclaiming, transporting, unloading and other actions in a working cycle work alternately. The development and use of cranes in the market are becoming more and more extensive.

Crane slewing ring bearing-structure type

1.Four contact ball slewing bearings

2.Cross roller slewing bearings

3.Double row ball slewing bearings

4.Triple row roller slewing bearings

5.Ball and roller combined slewing bearings;

Single row four point contact ball slewing bearings

This kind of slewing bearings can support high dynamic loads, transmitting axial and radial forces simultaneously as well as the resulting tilting moments. Applications of this kind of bearings are hoisting, mechanical handling and general mechanical engineering etc.

Single row cross roller slewing bearings

This kind of bearings can support combinations of large radial force, medium axial force and tilting moment with small or zero clearance. Main applications of this kind of bearings are hoisting and mechanical handling and general mechanical engineering etc.

Double row different ball diameter slewing bearings

This kind of bearings can support high static loads with simple structures. They are mainly used in situations with variation load position and direction and continuously rotating. Main applications of this kind of bearings are deck hoisting, mining and material handling etc.

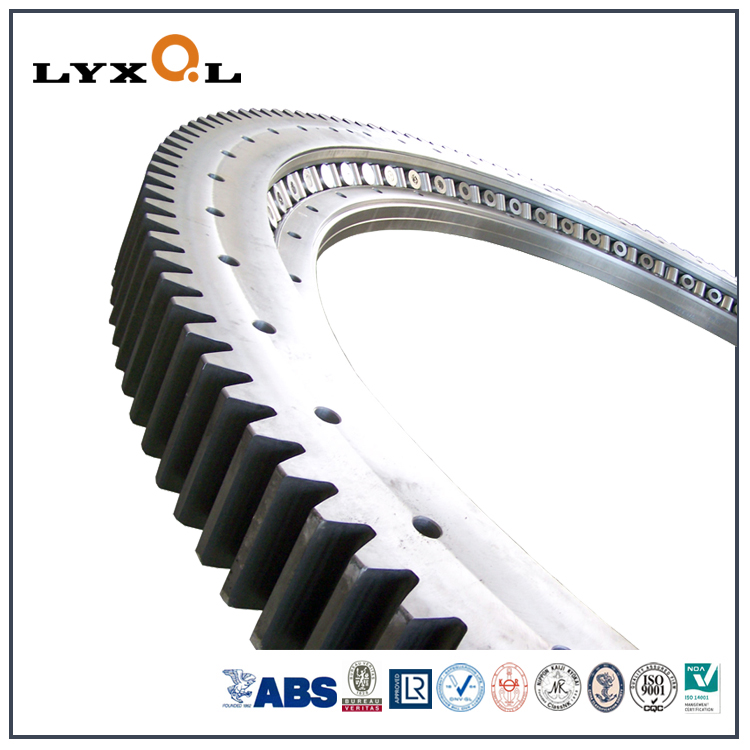

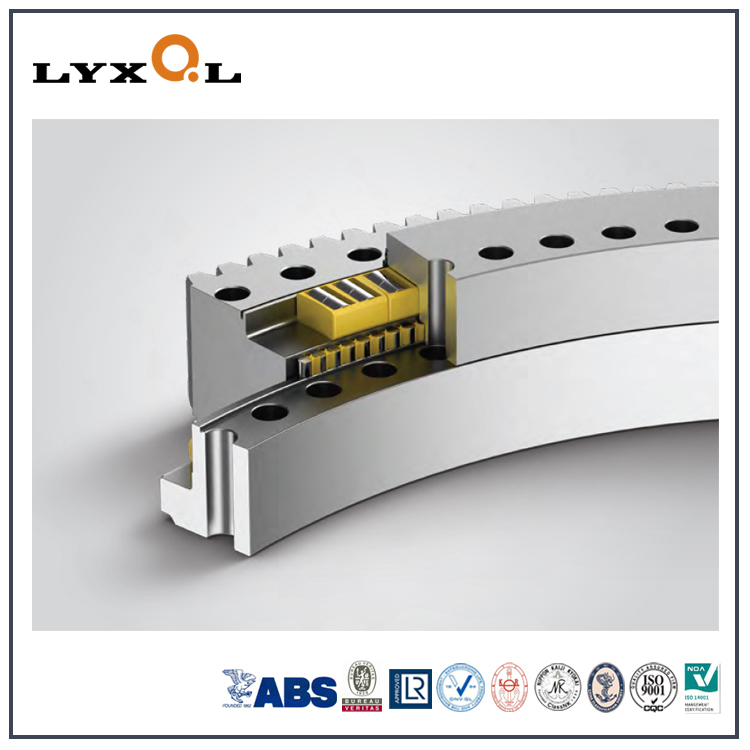

Triple row cylindrical roller slewing bearings

This kind of bearings has high load carrying capacity. Under same loads, this kind of bearings has much smaller diameters which can make the installation much compact, as different kinds of loads are supported by different races and rollers. Main applications of this kind of bearings are hoisting, mechanical handling, mining and materials handling, offshore technology and general mechanical engineering etc.

Roller/ball combination slewing bearings

This kind of bearings can support high axial load and low tilting moments. Usually they are large diameter slewing bearings. Applications of this kind of bearings are mining and materials handling etc.

Crane slewing ring ------Technical Data:

1.Inner ring and outer ring material: 42CrMo, 50Mn

2.Steel ball or roller material: Gcr15, Gcr15 SiMn, 304 Stainless steel, 440 Stainless steel

3. Precision: P0. P6. P5.

4. Outside diameter: 1000~17000mm

5. Cage/retainer: Nylon or Steel Cage

6: Seal: NBR, Oil resistant rubber,Viton,Skeleton oil seal

Crane slewing bearing------Surface treatment:

1: black surface treatment

2: Surface sandblasting and painting

3: Surface chrome plating

4: Surface spray zinc treatment

5: Surface phosphating treatment

6: Dacromet treatment

Crane slewing ring------Packaging Details:

Step 1: Covered with the anti-rust oil

Step 2: wrapped with the plastic film;

Step 3: Packed with Kraft paper and professional belts;

Step 4: Put into wooden box to avoid the rust or the moist;

Remark: Normally, plastic film+ Kraft +belt+ wooden box, but customized packing available,

Crane slewing ring bearing--- Advantages:

1. Good quality and competitive price

2. Trial order accepted

3. ISO certified company

4. OEM and ODM accepted

5. Can design and produce non-standard models according to the special requirements of customers.

6.Can provide BV, LR,DNV,CCS, NK,KR, GL,ABS certificate

Crane slewing ring bearing- Maintain

1. The slewing bearing should be greased regularly. According to different types of slewing bearings, the specific grease filling time is as follows: the ball type is filled with grease every 100 hours of operation; the roller type is filled with grease every 50 hours of operation .

2. The sundries on the surface of the slewing ring should be removed frequently during use, and the sealing strip of the slewing ring should be checked for aging, cracking, damage or separation. If one of these conditions occurs, the sealing strip should be replaced in time to prevent debris from entering the raceway and the loss of grease.

3.Pay close attention to the operation of the slewing ring during use. If you find that the noise, impact, or power suddenly increases, you should stop the machine immediately for inspection until all the faults are eliminated, and disassemble and inspect if necessary.